Lean Manufacturing – Reducing Material Wastage in Steel Production

Problem 1: Eliminating Unplanned Downtime with Predictive Maintenance

Nothing destroys a day like getting a call at midnight that the induction furnace is not working. But it wasn’t just about that moment—it wasn’t a single problem it was a chain reaction of issue:

- Workers sitting idle but still getting paid

- Fuel and energy wasted on restarts

- Customers complaining about delays in delivery.

- Rush jobs and overtime to make up lost time

- Number of defects increased because everyone’s stressed and rushing

I was losing around 15-20% of my productive capacity due to these unexpected breakdowns. But I thought, “It is normal for steel manufacturing plant right?”

Why This Happens:

The industry consultants explained something eye-opening: unplanned downtime is rarely truly “unplanned.” Equipment gives warning signs—vibrations, temperature changes, unusual noises, reduced performance. The problem is, we’re not set up to catch these signals early.

We were doing reactive maintenance fix it when it breaks. Every other industry moved past this decades ago, but many steel plants are stuck here.

The Solution That Worked:

The first thing the consulting team did was diagnosing the process and fixing the issue by implementing a predictive maintenance system. It was not some high-tech expensive software—just practical monitoring:

- Equipment Monitoring: IoT sensors on our machines like furnace, rolling mill, and main motors tracking temperature, vibration, and power consumption

- Weekly Inspection: Created simple checklists for maintenance team to inspect equipment systematically

- Maintenance Scheduling: Planned maintenance during low-demand periods instead of random shutdowns

- Spare Parts Strategy: Analysed past failures and stocked critical spares

The Result: Within six months, unplanned downtime dropped by 32%. It was not 100% but it was lesser than before only in 6 months. It was a great achievement. Equipment that used to fail monthly now runs smoothly for entire quarters.

The ROI? Those ₹2 lakh investment on sensors reduced downtime that would have cost us ₹12 lakhs. In addition to this delivery time is also improved.

Problem 2: Process Optimization: StreamliningPlant Workflows

We’d been running our rolling mill the same way for 12 years. Same layout, same material handling process, same scheduling system. Thinking it is working properly.

But here’s what I didn’t see:

- Raw materials being moved 8 different times before reaching the furnace

- Workers walking excessive distances throughout the day

- Work is distributed unevenly across stations as a result few remains idle

- Work orders were hard to track due to inconsistency in recording

- Setup times that ate into productive time

Why This Happens:

When you’re engaged in day-to-day operations, you can’t give time to the inefficiencies. It’s like being in a messy room for years—you are so used to it that you stop noticing the mess. We had gradually accepted work-arounds and inefficiencies as “just how we handle things.”

Process optimization isn’t about working harder. It’s about working smarter.

The consultants introduced me to “value stream mapping”—basically drawing out our entire production process step by step. When I saw it on paper, I was shocked at how convoluted it was.

Here’s what we changed:

- Redesign the layout: Rearranged machineries to minimize material movement

- Material Flow: Reduced handling movement from 8 moves to 3 moves—materials now flow logically through production

- Digital Work Orders: Simple app on tablets showing real-time job status

- Scheduling System: Proper sequencing to minimize changeovers and setup time

- Standard Operating Procedures: Documented standardized practices so everyone does things the optimal way

The Result: Material handling time reduced by 35%. We freed up 20% more floor. Setup times reduced to 28%.

Workers aren’t frustrated anymore. The process makes sense, and they can focus on quality work instead of fighting the system.

Problem 3: Driving Productivity through Workforce Training and Standard SOPs

I’ll be honest—I used to think my workers were the problem they were lacking skills. Production was slow, quality issues were common, nobody seemed to take ownership. I was frustrated.

The consultants helped me understand: my workers weren’t lazy or incompetent. They were working within a broken system:

- No clarification regarding roles and responsibilities.

- No standard procedures for doing things

- Inadequate training for equipment and processes

- Poor communication between shifts and departments

- No organisational structure

- No feedback—good or bad—on their performance

- Safety concerns made them work slower and more cautiously

How can you expect great performance when people don’t know exactly what or how to do it optimally?

This wasn’t about pushing people harder—it was preparing them for success:

- Clear Role Definitions: Every position now is well defined. Everyone knows their responsibilities and standards

- Cross-Training: Workers trained on multiple machines so we have flexibility and they’re more valuable

- Daily Briefings: 15-minute morning meetings for discussing yesterday’s results, today’s plan, issues to address

- Performance Visibility: Dashboard showing real-time metrics—everyone knows how we’re doing

- Suggestion System: Workers can submit improvement ideas

The Result: Worker productivity increased 28%. But more importantly:

- Safety incidents down 55%

- Employee turnover dropped from 28% to 8% annually

- Worker engagement surveys improved from 42% to 78%

- Quality defects reduced 60%

Problem 4: Lean Manufacturing: Reducing Material Wastage in Steel Production

We were having 8-10% material wastage. Scrap steel, off-spec products, trim waste, rework. I thought this was industry standard. But when the consultants told me plants running at 3-4% wastage, I realized we were doing something wrong

Why This Happens:

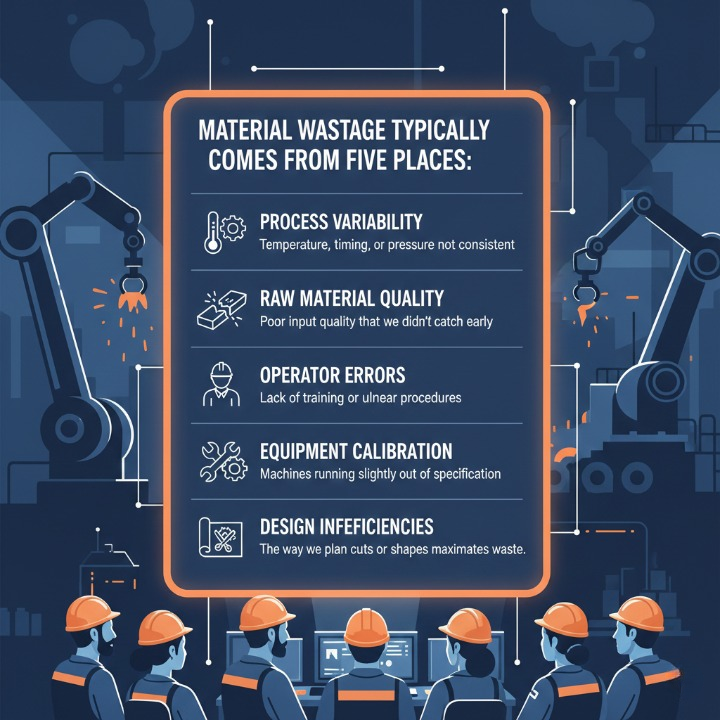

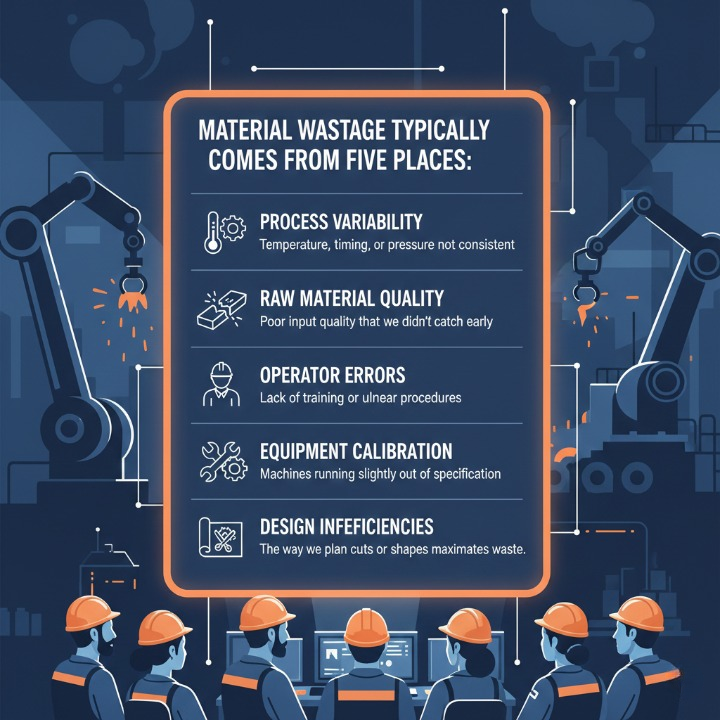

Material wastage typically comes from five places:

- Process variability: Temperature, timing, or pressure not consistent

- Raw material quality: Poor input quality that we was not noticeable earlier

- Operator errors: Lack of training or unclear procedures

- Equipment calibration: Machines running slightly out of specification

- Design inefficiencies: The way we plan cuts or shapes maximizes waste

We were experiencing all five, but didn’t have systems to address any of them.

This issue was resolved:

- Statistical Process Control: Started monitoring key parameters (temperature, pressure, timing) and set alert limits

- Raw Material Inspection: Implemented testing protocols before materials enter production

- Operator Training: Quality control training for every worker—they now check at each step

- Equipment Maintenance: Regular calibration schedules for all measuring and control equipment

- Waste Tracking: Started tracking exactly where scrap comes from to identify patterns

The big breakthrough? We discovered that 40% of our wastage came from inconsistent furnace temperatures. Fixed the control system, trained operators on temperature management, and scrap rates dropped.

Material wastage dropped from 9% to 4.2%. That’s a 53% reduction in scrap.

Financial impact? Saving ₹18 lakhs annually on materials alone. That money goes straight to the bottom line.

Problem 5: Energy Costs That Seemed Uncontrollable

Our monthly electricity bills were increasing. I thought, “That’s just the cost of running a steel plant.” We weren’t tracking which processes used how much energy, when consumption spiked, or what we could do to resolve it.

Energy is often the second-largest cost after raw materials, but it’s not monitored. We treat power as a fixed cost when it’s actually highly variable and controllable.

The industry consultants did an energy audit and found huge opportunities:

- Energy Monitoring: Installed sub-meters on major equipment to see actual consumption

- Peak Demand Management: Identified that we were running non-critical equipment during peak hours

- Operational Changes: Rescheduled heavy processes to off-peak hours where possible

- Equipment Upgrades: Replaced machines with high- efficiency versions, installed Variable Frequency Drives and improved furnace insulation.

- Power Factor Correction: Installed capacitor banks to improve power factor and reduce penalties

The industry consultants also helped us negotiate a better power contract based on our actual consumption pattern. Energy cost per ton of steel produced decreased 18%. Annual savings: ₹9 lakhs.

Plus, the improved power factor reduced our peak demand charges by another ₹3 lakhs annually.

Why Us?

Why Us?  Resources

Resources  Support

Support